Noga Engineering & Technology: Simple Yet Sophisticated Quality Tools

Machinists help create our world. Without them, the bolts, pistons, or other elements that make our machinery run wouldn't be possible. They use a wide variety of tools to achieve their aim from deburring tools to machinist blocks and CNC machines. Machine tools are a significant feature of this environment. Industry 4.0 has brought with it a sea of opportunities and scope for innovation. Globally, machine tools have fluctuating quality products. Not every manufacturer takes the curves and composition of the metal tool seriously, and therefore there are many `jack of all trades, but master of none' in this domain.

Based out of Shlomi, Israel, Noga Engineering & Technology has been an undisputed leader in the manufacturing of Deburring Systems, Holding systems, and Cutting Fluid applicators. Having a market for its products in more than 70 countries across the globe, Noga Engineering has an excellent distributor network and partners.

The company's core segments of products are Hand Deburring systems, Holding System, Cooling System, Hold It line Holding Systems for the professional cinama/photography industry, and Tag Dental equipments such as dental implants, instruments, superstructures, regenerative solutions and more. More so, Noga Engineering is working towards launching its newest portfolio called Noga MT (Noga Machine Tools). This division will be focused on Machine deburring and finish tools that will provide efficiency and high quality and precise deburring for the high end mass production machining industry.

Noga Engineering & Technology has subsidiaries in Holland, Germany and Colombia. "Ever since our inception in 1980, we are committed to provide high quality products, to keep innovative and to increase every day the partnership with our loyal customers," expresses Michel Allouch, CEO, Noga Engineering & Technology. Michel has secured a B.Sc. degree in Civil Engineering from the Technion, and an MBA Real Estate Valuation and Management from the Haifa University, Israel. He brings 20 years of industry experience across technology, R&D, marketing, Business Development and management globally.

Noga is proud of its products design and development, quality, service and product range.

Additionally, Noga holds a daughter company Noga Medical Products LTD, which develops, produces and sells dental implants, instruments, superstructures, regenerative solutions and other premium quality products in 27 countries via the known brand Tag Dental.

Broadest Range Of Precision High Quality Tools

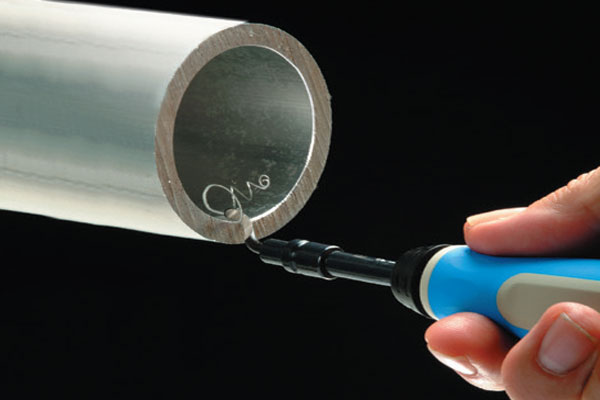

Where shops once relied on hand-sharpened knives or triangular files turned scraping tool, they now have a wide variety of deburring blades, blade materials, and handles to choose from. Noga offers dozens of application specific blade geometries and materials. These include blades for plain holes, cross holes, and deep holes, straight edges or curved, hard and soft metals and plastics, as well as right and left hand blades, single or double edge, coated or uncoated carbide, highspeed steel (HSS), and ceramic blades; the list goes on.

Noga provides to its distributors, customers high level of technical support, seminars, tutorial videos and all kind of consultation in order to meet any specific need and and to provide the most cost effective solution to the end user.

Feedback Supported Companies

Noga Engineering & Technology has evolved amidst a traditional market that presented considerable challenges. Businesses thriving on metal components or machines or the metal industry in general have been a strong boost for Noga. Consequently, these customers are very particular about the quality of the products being used for their assets. Accordingly, Noga Engineering & Technology has ensured that the tools that come out of its factory are of the highest standards. By continuous listening to the market needs and using latest technologies we were able during the years to develop patented tools to solve deburring problems that before remained unsolved. When needed we use experts in fields such as: ergonomics, material flow, and more, to provide the best and convenient tool possible.

Every feedback from the market is being inspected to ensure continuous improvement of our products.

"For more than 40 years, NOGA has been recognized worldwide for its state-of-the-art Hand Deburring Tools, designed to be used extensively in industrial applications. Our customers see us as the one that always has innovative new products and solutions. We have maintained a reputation for products with a very high quality and we strive to continue and do so in numerous segments of market," adds Michel.

Not Just Global, But Multi Local

Noga Engineering & Technology is more than just a multinational company, it is a multi-local company. In every country that Noga serves its products and solutions, it maintains a local touch with its end consumers by offering essential & efficient after sales support. This is highly appreciated by Noga's customers around the globe. The credit to such an approach goes to the extremely valuable partners that Noga takes pride in.

Noga Engineering & Technology has differentiated itself from various other similar tool manufacturers on the back of this unique approach to serve clients even after sales. So it's not just the products that are of highest quality, it's also the services that make Noga Engineering & Technology the most sought after company.

As an example, one of the largest manufacturers of motorcycles had placed a request with Noga to build a special blade for its robot that will remove burrs from one of their parts. Noga delivered perfection and the client is still buying from Noga to this day. Another large aviation company that manufactures aircraft engines requested for a special carbide blade to remove burrs from one of their parts located in the engine. Again, Noga developed the blade which provides the specific solution and solved their problem.

Future Roadmap

Michel appointment as the CEO at Noga witnessed a whole new transformation within the organization in terms of the talent distribution. Michel made crucial arrangements to double the number of engineers and R& D workforce at Noga. More so, Noga has invested a lot in the last two years to integrate new technologies in the production right from latest automated machines to robotics, thereby bringing transformation inhouse.

Michel emphasizes on the fact that more than anything, Noga Engineering & Technology derives its success from the efforts of the employees who have furnished their dedicated support and talent to the organization. Noga supports its staff to study and attend seminars on various technologies or new sophisticated machines that will provide new solutions. The firm also educates them as to how important it is to develop high quality tool and how to inspect the tool on each stage of their production.

Noga's Quality assurance managers and their team watch each step of the production of every item coming out of Noga's factories. Noga's workforce comprises of people who have been in the organization for the last 30-40 years bestowing their gift of experience in the success & growth of Noga. Noga's immediate plan of action will be to maintain and keep the leadership position in the market. The firm also intends to grow by significant amount in the new markets while also expanding its outreach in the overall medical industry. "We will continue to develop new and innovative tools that will provide practical solutions to our customers. We also intend to develop new sets of tools that will provide a wide range of application solutions in additional completely new markets," concludes Michel.

Based out of Shlomi, Israel, Noga Engineering & Technology has been an undisputed leader in the manufacturing of Deburring Systems, Holding systems, and Cutting Fluid applicators. Having a market for its products in more than 70 countries across the globe, Noga Engineering has an excellent distributor network and partners.

Noga engineering &technology is more than just a multinational company, it is a multi-local company

The company's core segments of products are Hand Deburring systems, Holding System, Cooling System, Hold It line Holding Systems for the professional cinama/photography industry, and Tag Dental equipments such as dental implants, instruments, superstructures, regenerative solutions and more. More so, Noga Engineering is working towards launching its newest portfolio called Noga MT (Noga Machine Tools). This division will be focused on Machine deburring and finish tools that will provide efficiency and high quality and precise deburring for the high end mass production machining industry.

Noga Engineering & Technology has subsidiaries in Holland, Germany and Colombia. "Ever since our inception in 1980, we are committed to provide high quality products, to keep innovative and to increase every day the partnership with our loyal customers," expresses Michel Allouch, CEO, Noga Engineering & Technology. Michel has secured a B.Sc. degree in Civil Engineering from the Technion, and an MBA Real Estate Valuation and Management from the Haifa University, Israel. He brings 20 years of industry experience across technology, R&D, marketing, Business Development and management globally.

Noga is proud of its products design and development, quality, service and product range.

Additionally, Noga holds a daughter company Noga Medical Products LTD, which develops, produces and sells dental implants, instruments, superstructures, regenerative solutions and other premium quality products in 27 countries via the known brand Tag Dental.

Broadest Range Of Precision High Quality Tools

Where shops once relied on hand-sharpened knives or triangular files turned scraping tool, they now have a wide variety of deburring blades, blade materials, and handles to choose from. Noga offers dozens of application specific blade geometries and materials. These include blades for plain holes, cross holes, and deep holes, straight edges or curved, hard and soft metals and plastics, as well as right and left hand blades, single or double edge, coated or uncoated carbide, highspeed steel (HSS), and ceramic blades; the list goes on.

Noga provides to its distributors, customers high level of technical support, seminars, tutorial videos and all kind of consultation in order to meet any specific need and and to provide the most cost effective solution to the end user.

Feedback Supported Companies

Noga Engineering & Technology has evolved amidst a traditional market that presented considerable challenges. Businesses thriving on metal components or machines or the metal industry in general have been a strong boost for Noga. Consequently, these customers are very particular about the quality of the products being used for their assets. Accordingly, Noga Engineering & Technology has ensured that the tools that come out of its factory are of the highest standards. By continuous listening to the market needs and using latest technologies we were able during the years to develop patented tools to solve deburring problems that before remained unsolved. When needed we use experts in fields such as: ergonomics, material flow, and more, to provide the best and convenient tool possible.

Every feedback from the market is being inspected to ensure continuous improvement of our products.

"For more than 40 years, NOGA has been recognized worldwide for its state-of-the-art Hand Deburring Tools, designed to be used extensively in industrial applications. Our customers see us as the one that always has innovative new products and solutions. We have maintained a reputation for products with a very high quality and we strive to continue and do so in numerous segments of market," adds Michel.

Not Just Global, But Multi Local

Noga Engineering & Technology is more than just a multinational company, it is a multi-local company. In every country that Noga serves its products and solutions, it maintains a local touch with its end consumers by offering essential & efficient after sales support. This is highly appreciated by Noga's customers around the globe. The credit to such an approach goes to the extremely valuable partners that Noga takes pride in.

Noga Engineering & Technology has differentiated itself from various other similar tool manufacturers on the back of this unique approach to serve clients even after sales. So it's not just the products that are of highest quality, it's also the services that make Noga Engineering & Technology the most sought after company.

As an example, one of the largest manufacturers of motorcycles had placed a request with Noga to build a special blade for its robot that will remove burrs from one of their parts. Noga delivered perfection and the client is still buying from Noga to this day. Another large aviation company that manufactures aircraft engines requested for a special carbide blade to remove burrs from one of their parts located in the engine. Again, Noga developed the blade which provides the specific solution and solved their problem.

Future Roadmap

Michel appointment as the CEO at Noga witnessed a whole new transformation within the organization in terms of the talent distribution. Michel made crucial arrangements to double the number of engineers and R& D workforce at Noga. More so, Noga has invested a lot in the last two years to integrate new technologies in the production right from latest automated machines to robotics, thereby bringing transformation inhouse.

Michel emphasizes on the fact that more than anything, Noga Engineering & Technology derives its success from the efforts of the employees who have furnished their dedicated support and talent to the organization. Noga supports its staff to study and attend seminars on various technologies or new sophisticated machines that will provide new solutions. The firm also educates them as to how important it is to develop high quality tool and how to inspect the tool on each stage of their production.

Noga's Quality assurance managers and their team watch each step of the production of every item coming out of Noga's factories. Noga's workforce comprises of people who have been in the organization for the last 30-40 years bestowing their gift of experience in the success & growth of Noga. Noga's immediate plan of action will be to maintain and keep the leadership position in the market. The firm also intends to grow by significant amount in the new markets while also expanding its outreach in the overall medical industry. "We will continue to develop new and innovative tools that will provide practical solutions to our customers. We also intend to develop new sets of tools that will provide a wide range of application solutions in additional completely new markets," concludes Michel.